The capacitors that we use for high-frequency bypass (decoupling) are MLCC capacitors, which are multilayer ceramic capacitors. The main reason is that the high-frequency characteristics are good, and the band-limited frequency point of the capacitor can be found by using the SIPCAP software.

The comparison between tantalum capacitors and aluminum capacitors is as follows:

The traditional method of classification of electrolytic capacitors is based on the anode material, such as aluminum or tantalum. Therefore, electrolytic capacitors are divided into the following categories:

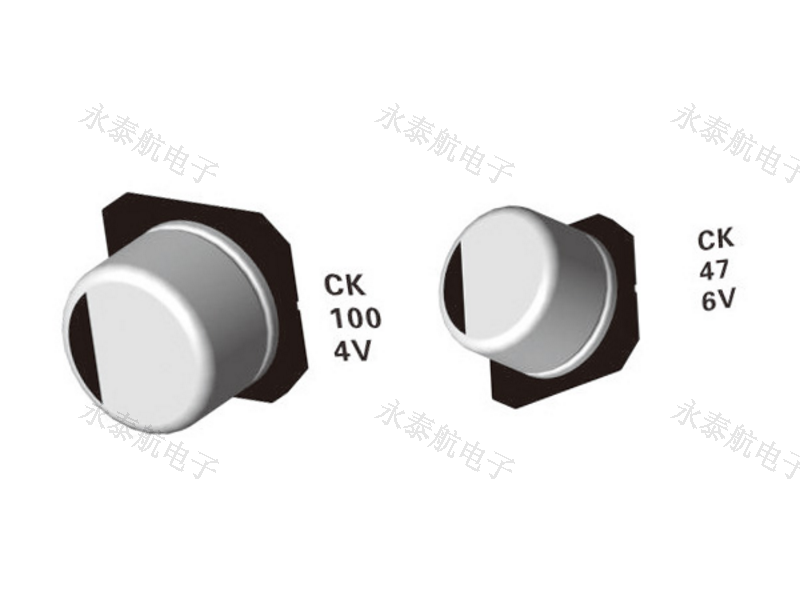

1. Aluminum electrolytic capacitors. No matter it is SMT chip technology or direct plug-in type, as long as their anode material is aluminum, then they are called aluminum electrolytic capacitors. The packaging method of the capacitor is not directly related to the quality of the capacitor itself, and the performance of the capacitor depends only on the specific model.

2. Tantalum electrolytic capacitors. The anode is made of tantalum. At present, many tantalum electrolytic capacitors are mounted by SMD, and their shells are generally encapsulated by resin (the same package may also be aluminum electrolytic capacitors). However, the cathode of a tantalum capacitor is also an electrolyte.

The traditional view in the past was that tantalum capacitors have better performance than aluminum capacitors, because the dielectric of tantalum capacitors is tantalum pentoxide generated after anodization, and its dielectric capacity (usually represented by ε) is higher than that of aluminum oxide dielectric of aluminum capacitors. high. Therefore, under the same capacity, the volume of tantalum capacitors can be made smaller than aluminum capacitors. (The capacitance of an electrolytic capacitor depends on the dielectric capacity and volume of the medium. In the case of a certain capacity, the higher the dielectric capacity, the smaller the volume can be made, otherwise, the larger the volume needs to be.) The properties of tantalum are relatively stable, so tantalum capacitors are generally considered to be better than aluminum capacitors.

But this method of judging capacitor performance based on anode is outdated. At present, the key to determining the performance of electrolytic capacitors is not the anode, but the electrolyte, which is the cathode. Because different cathodes and different anodes can be combined into different types of electrolytic capacitors, their performance is also very different. The performance of capacitors using the same anode can vary greatly due to different electrolytes. In short, the impact of the anode on the capacitor performance is far less than that of the cathode.

The cathode material is the other plate of the capacitor, and the cathode is the electrolyte of the capacitor. The cathodes of capacitors are basically as follows:

1. Electrolyte. Electrolyte is the most traditional electrolyte. The electrolyte is obtained by heating GAMMA butyrolactone organic solvent and weak acid salt capacitor. The cathodes of aluminum electrolytic capacitors in the ordinary sense that we see are all this electrolyte. There are many advantages to using electrolyte as a cathode. The first is that the contact area between the liquid and the medium is large, which helps to increase the capacitance. The second is the electrolytic capacitor made of electrolyte, which can withstand a high temperature of 260 degrees, so that it can be wave soldered (wave soldering is an important process of SMT patch installation), and the voltage resistance is also relatively strong. In addition, for electrolytic capacitors that use electrolyte as the cathode, when the medium is broken down, as long as the breakdown current does not continue, the capacitor can heal itself. But the electrolyte also has its shortcomings. The first is that it is easy to volatilize and leak in a high-temperature environment, which has a great impact on life and stability. Under high temperature and high pressure, the electrolyte may vaporize instantly, and increase its volume to cause an explosion (which is what we often call explosive slurry); The ion conduction method used in the electrolyte has a very low conductivity, only 0.01S (conductivity, the reciprocal of ohms)/CM, which causes the ESR (equivalent series resistance) of the capacitor to be extremely high.

2. Traditionally, the performance of tantalum capacitors is believed to be better than that of aluminum capacitors. The main reason is that tantalum and manganese dioxide cathodes have a better performance than aluminum electrolyte capacitors. If the cathode of the aluminum electrolyte capacitor is replaced with manganese dioxide, its performance can actually be improved a lot.

manganese dioxide. Manganese dioxide is the cathode material used in tantalum capacitors. Manganese dioxide is a solid, the conduction method is electronic conduction, and the conductivity is ten times (0.1S/CM) of electrolyte ion conduction, so ESR is lower than that of electrolyte. Therefore, traditionally, people think that tantalum capacitors are much better than aluminum capacitors, and there is no danger of leakage of solid electrolyte. In addition, the high temperature resistance of manganese dioxide is also better, and the instantaneous temperature it can withstand is about 500 degrees. The disadvantage of manganese dioxide is that high temperature is easily generated when the polarity is reversed. Oxygen is released in a high temperature environment. At the same time, the tantalum pentoxide dielectric layer undergoes crystalline changes, becomes brittle and cracks, and oxygen flows along the cracks and tantalum powder. The mixture exploded. In addition, the price of this cathode material is relatively expensive. (Compared with aluminum electrolyte capacitors, although they are all explosions, the principle is different. How many people can notice this?