1. Different performance:

Performance is the requirement of use, and maximum demand is the requirement of use. If a metal oxide film capacitor is used for filtering in the power supply part of the TV, the capacitor capacity and withstand voltage required for filtering must be achieved. I am afraid that only one power supply can be installed in the case. Therefore, only polar capacitors can be used as filters, and polar capacitors are irreversible. That is to say, the positive pole must be connected to the high potential end, and the negative pole must be connected to the low potential end. Generally, electrolytic capacitors are above 1 microfarad for coupling, decoupling, power filtering, etc. Most of the non-polar capacitors are below 1 microfarad and participate in resonance, coupling, frequency selection, current limiting, and so on. Of course, there are also large-capacity and high withstand voltage, which are mostly used for reactive power compensation of electric power, phase shifting of motors, and variable frequency power shifting.

2. Different structure:

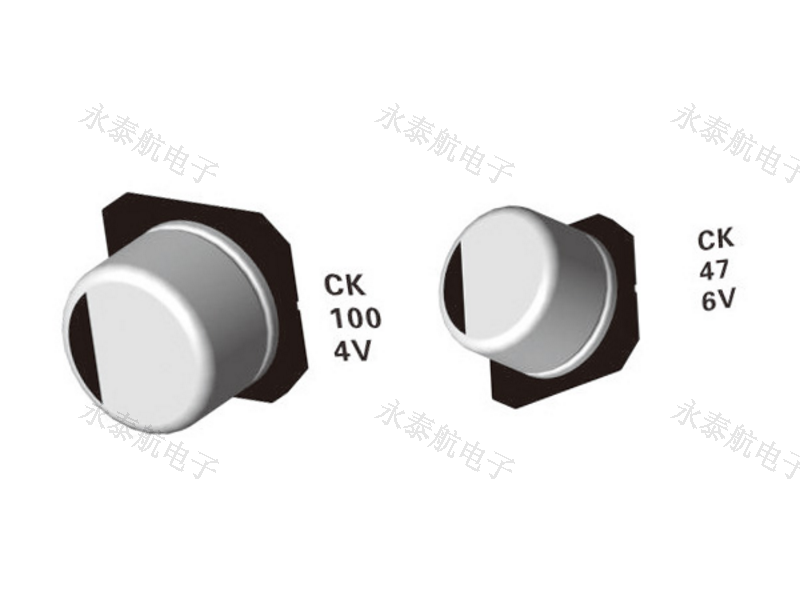

In principle, without considering the tip discharge, any shape of capacitor can be used in the environment. The commonly used electrolytic capacitors (with polarized capacitors) are round, and square ones are rarely used. The shapes of non-polar capacitors vary. Like tube, deformed rectangle, sheet, square, round, combined square and round, etc., depending on where they are used. Of course, there are also intangibles. The intangibles here refer to distributed capacitance. Distributed capacitance must not be ignored in high frequency and intermediate frequency devices.

3. Different media:

What is the medium? To put it bluntly, it is the substance between the two plates of the capacitor. Most of the polar capacitors use electrolyte as the dielectric material, usually the same volume of the capacitor has a large capacity. In addition, polarized capacitors manufactured by different electrolyte materials and processes have different capacities with the same volume. Furthermore, the pressure resistance is also closely related to the use of dielectric materials. There are also many non-polar capacitor dielectric materials, most of which use metal oxide film, polyester and so on. Because the reversible or irreversible performance of the medium determines the use environment of polar and non-polar capacitors.

4. The principle is the same:

(1) Both store charge and release charge; (2) The voltage on the plate (here, the electromotive force accumulated by the charge is called voltage) cannot be changed suddenly. (3) The difference lies in the different media, different performance, different capacity, and different structure, resulting in different use environments and uses. Conversely speaking, according to the needs of production practice, people have experimentally manufactured capacitors with various functions to meet the normal operation of various electrical appliances and the operation of new equipment. With the development of science and technology and the discovery of new materials, more high-quality and diversified capacitors will continue to emerge.